|

I-7530A-MR (Modbus RTU to CAN Converter)

|

The PLC, HMI and SCADA are popular in the various industrial control applications, but most of them don’t provide CAN interfaces. Users always experienced difficulties due to connecting the sensors or actuators which only have a CAN interface. The basic function of I-7530A-MR is compatible with I-7530A, and the “MR” stands for “Modbus RTU”. So, the I-7530A-MR supports Modbus RTU protocol in its RS-232/422/485 port. Modbus RTU is popular and widely supported by most of the PLCs, HMIs, and SCADAs. I-7530A-MR is helpful to use standard Modbus RTU protocol to access CAN networks without difficulties. And with the special designed firmware, beside normal received CAN message buffer, it offers special memory space to save up to 100 kinds of CAN messages which are urgent and must be processed immediately. The feature helps the PLC, HMI and SCADA to use Modbus RTU function code 3,4,16 to access CAN devices in a easy way.

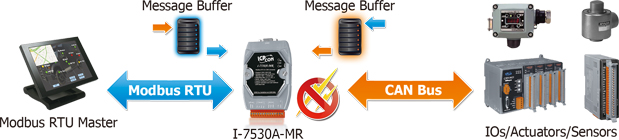

In Modbus RTU mode, it allows a Modbus RTU master to communicate with CAN devices on a CAN network. The following figure shows the application architecture of this mode.

Request For Quotation

Description

|

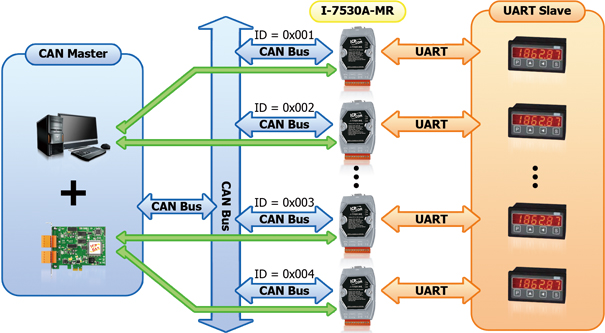

In pair-connection mode, this module provides the pair connection and transparent communication between the RS-232/485/422 devices via CAN bus. The application architecture may be as follows. |

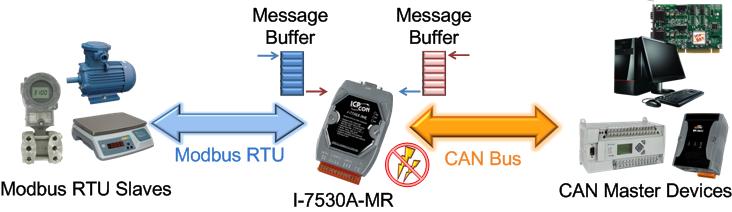

In the Modbus Master mode, it allows many Modbus RTU slaves to communicate with CAN devices on a CAN network. The following figure shows the application architecture in this mode. The Modbus master function can be supported in firmware version v1.11 or later.

Applications

|

|

|

|

|

|

|

Features

- RoHS Design

- Fully compatible with ISO 11898-2 standard

- Programmable CAN bus baud rate from 10 kbps to 1 Mbps or user-defined baud rate

- Support CAN bus acceptance filter configuration

- Support firmware update via RS-232

- Provide utility tool for module setting and CAN bus communication testing

- Built-in jumper to select 120Ω terminal resistor

- CAN buffer: 128 data frames ; UART buffer: 256 bytes

- Power, data flow and error indicator for CAN and UART status

- Hardware Watchdog design

- Convert CAN message to specific ASCII command string (Normal mode)

- Convert specific ASCII command string to CAN message (Normal mode)

- Provide the transparent communication between the RS-232/485/422 devices via CAN bus (Pair-connection mode)

- In Modbus Slave mode, I-7530A-MR supports function code 0x03, 0x04, 0x06 (firmware version v1.11 or later), and 0x10 of Modbus RTU command for reading or writing CAN message (Modbus Slave mode). (New)

- Support Modbus Master function (firmware version v1.11 or later). (New)